Understanding Inventory Locations and Warehouses in Business Central

Before diving into this Dynamics 365 Business Central training topic, it is essential to understand the distinction between inventory locations and warehouses in Dynamics 365 Business Central.

Inventory Locations are places where inventory is stored, tracked, and managed. These can include physical spaces like storerooms, retail locations, or any place where goods are kept.

Warehouses, on the other hand, provide a more complex and detailed structure for managing inventory. Warehouses in Business Central support advanced features such as bin management, warehouse receipts, and shipments, enabling more precise control over inventory movements and storage spaces.

Steps to Convert an Inventory Location to a Warehouse

Converting an inventory location to a warehouse in Dynamics 365 Business Central involves several key steps. Here is a comprehensive guide to help you through the process:

Step 1: Prepare Your Inventory Location

Before initiating the conversion, ensure that the inventory location is properly set up and all relevant data is accurate. This includes verifying stock levels, ensuring items are correctly categorized, and resolving any discrepancies in inventory records.

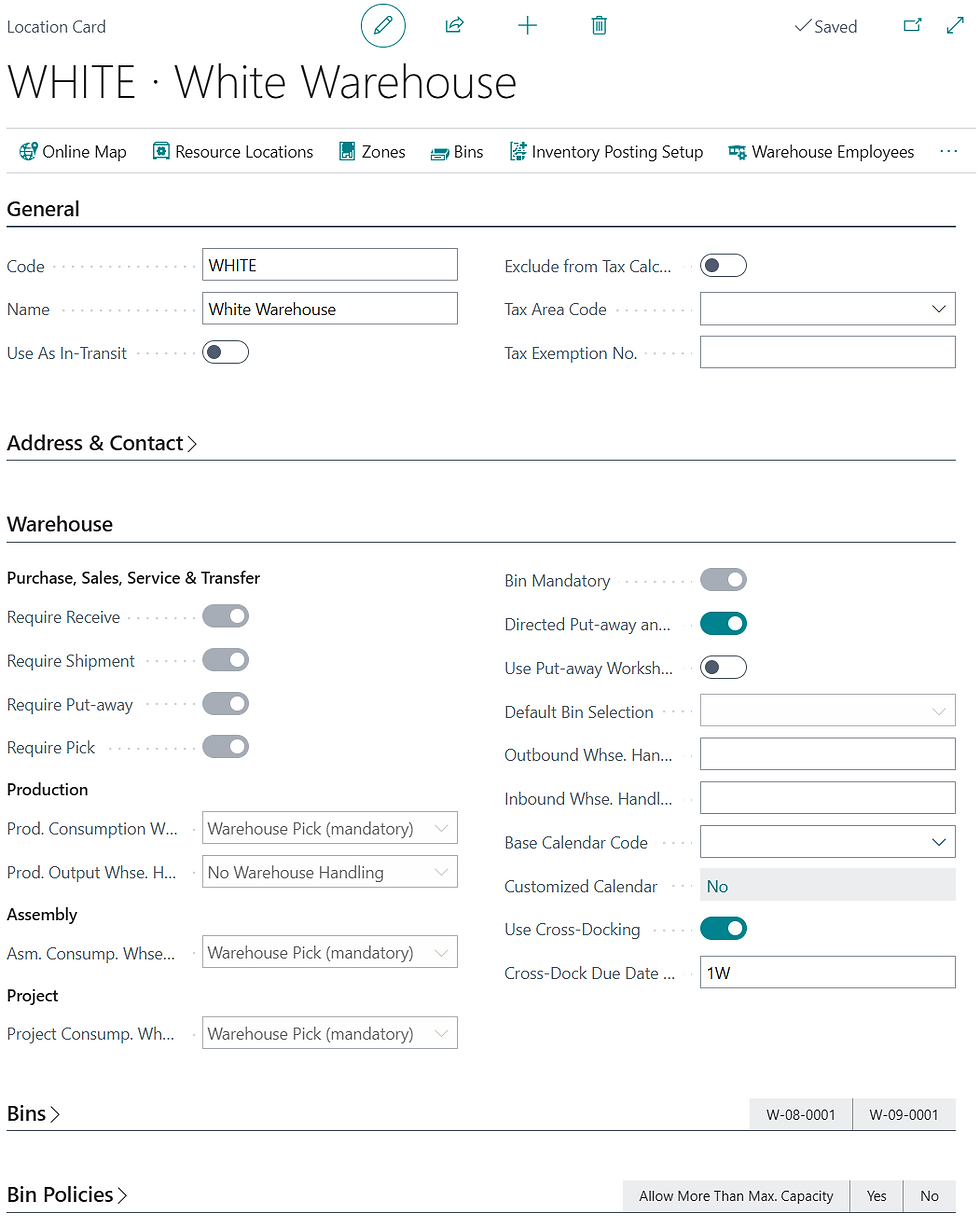

Step 2: Access the Location Card

Navigate to the Location Card in Dynamics 365 Business Central. You can do this by searching for "Locations" in the search bar and selecting the appropriate inventory location you wish to convert.

Step 3: Enable Warehouse Management

On the Location Card, locate the Warehouse FastTab. Here, you will find various settings that need to be configured for your location to function as a warehouse. Key settings include:

Directed Put-away and Pick: Enable this option if you want to guide the put-away and picking processes within the warehouse.

Require Receive: Check this box to mandate that all items received must be processed through warehouse receipts.

Require Shipment: Enable this setting to ensure all outbound items are processed through warehouse shipments.

Bin Mandatory: This option makes it compulsory to assign bins to items within the warehouse, enabling more precise inventory tracking.

Step 4: Set Up Bins

Bins are essential for detailed inventory management within a warehouse. To set up bins:

Navigate to the Bins section from the Location Card.

Create bins by specifying Bin Codes and descriptions, ensuring they are logically organized to reflect the physical layout of the warehouse.

Assign items to the appropriate bins to facilitate easy identification and tracking within the warehouse.

Step 5: Configure Warehouse Processes

Depending on your business requirements, you may need to set up various warehouse processes, such as:

Warehouse Receipts: Define how items are received and documented upon arrival at the warehouse.

Warehouse Shipments: Establish procedures for items being shipped out of the warehouse.

Internal Picks and Put-aways: Create processes for internal movement of items within the warehouse.

These configurations ensure that all warehouse operations are streamlined and adhere to established protocols.

Step 6: Test the Warehouse Setup

Once all configurations are complete, it is crucial to test the warehouse setup to ensure everything functions correctly. Perform test transactions, such as receiving and shipping items, to verify that all processes are working as intended. Address any issues or inconsistencies that arise during testing.

Step 7: Train Staff

Proper training is essential for a smooth transition from an inventory location to a warehouse. Ensure that all relevant staff members are trained on the new warehouse processes, including how to use bins, handle warehouse receipts and shipments, and manage inventory within the warehouse.

Step 8: Go Live

After thorough testing and training, you are ready to go live with your new warehouse setup. Monitor the initial operations closely to identify and resolve any teething problems. Make any necessary adjustments to optimize warehouse efficiency and performance.

Benefits of Converting an Inventory Location to a Warehouse

The conversion of an inventory location to a warehouse in Dynamics 365 Business Central offers several benefits, including:

Enhanced Inventory Control: More precise tracking of inventory movements and storage locations.

Improved Efficiency: Streamlined processes for receiving, shipping, and internal movements of items.

Optimized Space Utilization: Better organization and utilization of storage space through bin management.

Increased Accuracy: Reduced errors in inventory records and improved accuracy in stock levels.

Scalability: The warehouse setup in Business Central can grow with your business, accommodating increasing inventory levels and complexity.

Conclusion

Converting an inventory location to a warehouse in Dynamics 365 Business Central is a strategic move that can significantly enhance your inventory management capabilities. By following the steps outlined in this guide, you can ensure a smooth transition and unlock the full potential of your warehouse operations. Whether you are looking to improve efficiency, accuracy, or scalability, leveraging the advanced features of Business Central's warehouse management module is a vital step towards achieving your business goals.

Comments