Introduction

Configuring machine and work centers in Microsoft Dynamics 365 Business Central is crucial for efficient production management. Proper setup ensures accurate production scheduling, resource allocation, and cost management. This Dynamics 365 Business Central training blog post provides detailed, step-by-step instructions and best practices for configuring machine and work centers in Dynamics 365 Business Central.

Understanding Machine and Work Centers

In Dynamics 365 Business Central, machine centers represent individual machines or production resources, while work centers represent groups of machines or production resources. Both are essential for defining production capacities and scheduling.

Key Differences

Machine Centers: Focus on individual machines with specific capacities, calendars, and efficiencies.

Work Centers: Group multiple machines or resources, allowing for collective capacity and scheduling management.

Step-by-Step Configuration

1. Define Work Center Groups

Work center groups help organize and manage similar work centers. To define work center groups, follow these steps:

Navigate to Departments > Manufacturing > Setup > Work Center Groups, or use the global search functionality by typing "Work Center Groups".

Click New to create a new work center group.

Enter a Code and Description for the group.

Click OK to save the group.

2. Configure Work Centers

Work centers must be configured before adding machine centers. Follow these steps:

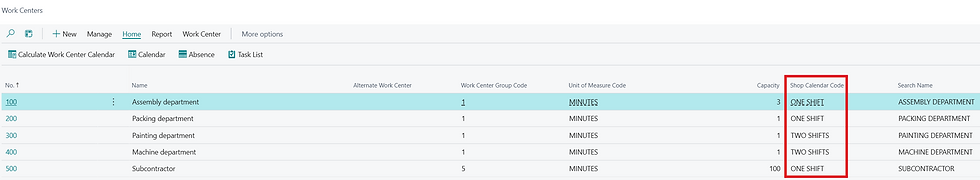

Navigate to Departments > Manufacturing > Setup > Work Centers, or use the global search functionality by typing "Work Centers".

Click New to create a new work center.

Fill in the Code and Description fields.

Select the Work Center Group created earlier.

Define the Unit of Measure and Capacity.

Set the Efficiency Percentage to reflect the work center’s efficiency compared to its standard capacity.

Define the work center’s Shop Calendar Code to determine its working hours and shifts.

Click OK to save the work center.

3. Configure Machine Centers

Machine centers represent individual machines or resources within a work center. Here’s how to configure them:

Navigate to Departments > Manufacturing > Setup > Machine Centers, or use the global search functionality by typing "Machine Centers".

Click New to create a new machine center.

Fill in the Code and Description fields.

Select the Work Center to which the machine center belongs.

Define the Unit of Measure and Capacity.

Set the Efficiency Percentage specific to the machine center.

Define the machine center’s Shop Calendar Code.

Click OK to save the machine center.

4. Set Up Shop Calendars

Shop calendars define the working hours and shifts for machine and work centers. Follow these steps to set up shop calendars:

Navigate to Departments > Manufacturing > Setup > Shop Calendars, or use the global search functionality by typing "Shop Calendars".

Click New to create a new shop calendar.

Enter a Code and Description for the calendar.

Define the Working Days and Shifts for the calendar.

Click OK to save the shop calendar.

5. Assign Shop Calendars to Work Centers

Assigning shop calendars ensures that the working hours and shifts are accurately reflected in production schedules:

Navigate to Departments > Manufacturing > Setup > Work Centers Centers, or use the global search functionality by typing "Work Centers".

Select the work center to which you want to assign a shop calendar.

In the Shop Calendar Code field, select the appropriate calendar.

Click OK to save the changes.

Best Practices for Configuration

To ensure optimal performance and accurate production management, consider the following best practices:

1. Standardize Naming Conventions

Implement consistent and descriptive naming conventions for work and machine centers. This practice simplifies identification and reduces errors.

2. Regularly Update Shop Calendars

Regularly review and update shop calendars to reflect changes in working hours, shifts, and holidays. Accurate calendars are critical for precise production scheduling

.

3. Monitor Efficiency Percentages

Periodically review and adjust the efficiency percentages of work and machine centers. This practice ensures that production schedules and capacity planning accurately reflect real-world conditions.

4. Train Personnel

Ensure that all relevant personnel are trained in the configuration and use of work and machine centers in Dynamics 365 Business Central. Proper training minimizes errors and maximizes the system’s benefits.

5. Conduct Regular Audits

Regularly audit work and machine center configurations to identify and correct discrepancies. Audits help maintain the integrity of production data and improve overall system performance.

Conclusion

Configuring machine and work centers in Dynamics 365 Business Central is essential for efficient production management. By following the step-by-step instructions and best practices outlined in this guide, you can ensure accurate production scheduling, resource allocation, and cost management. Properly configured machine and work centers contribute significantly to the overall success of your manufacturing operations.

For more detailed information or assistance with specific configurations, refer to the Dynamics 365 Business Central documentation or consult with a certified Dynamics 365 Business Central professional.

Comments